Email: [email protected]

2024.08.08

2024.08.08

Industry News

Industry News

Automatic noodle-making machines are designed with advanced precision control systems that employ sophisticated algorithms and microprocessors to oversee the entire production process. These systems meticulously control variables such as ingredient quantities, mixing durations, kneading speeds, and processing temperatures. By continuously monitoring these factors, the machine ensures that each step of the production process is executed with exactitude. The result is a product that is consistent in every aspect, from dough consistency to noodle texture.

The machines utilize high-precision metering devices and automated dispensers to measure and mix ingredients. These devices include digital scales, volumetric feeders, and augers that deliver precise amounts of flour, water, and additives. The accuracy of these measurements is crucial for maintaining a uniform dough mixture, which directly impacts the quality of the noodles. This automation minimizes human error and ensures that each batch adheres to the exact formulation, leading to consistent product characteristics.

Temperature control is critical in the noodle-making process to ensure optimal texture and quality. Automatic machines are equipped with advanced temperature regulation systems that include sensors, heaters, and cooling units. These components work together to maintain the precise temperatures required during different stages of production, such as dough mixing, cooking, and steaming. Consistent temperature management prevents issues such as overcooking or undercooking, which can affect the final product’s quality and texture.

The mixing and kneading processes are automated to ensure thorough and even processing of the dough. The machine's mixing chamber is designed with multiple paddles or blades that evenly incorporate ingredients, while its kneading function ensures the dough achieves the desired consistency. This automation eliminates variability caused by manual handling and ensures that each batch of dough is uniformly mixed and kneaded, resulting in consistent noodle quality.

Modern noodle-making machines are equipped with an array of quality control sensors that continuously monitor key parameters throughout the production process. These sensors measure variables such as dough viscosity, noodle thickness, and shape dimensions. Data collected by these sensors is analyzed in real-time, allowing the machine to make instantaneous adjustments to maintain quality standards. This proactive approach helps to identify and rectify any deviations from desired specifications before they impact the final product.

The shaping and cutting mechanisms in automatic machines are engineered with precision to ensure uniform noodle dimensions. These mechanisms use molds, rollers, and cutters that are calibrated to produce noodles of consistent size and shape. By maintaining uniformity in the noodle’s physical characteristics, the machine ensures even cooking and a consistent end product. This consistency is vital for achieving uniform texture and appearance across all batches.

To uphold product quality, automatic noodle-making machines require regular calibration of their mechanical and electronic components. Calibration involves adjusting the machine’s settings and sensors to ensure they operate within the specified tolerances. This process is essential for maintaining accurate ingredient measurements, temperature control, and shaping precision. Regular calibration prevents deviations that could compromise the consistency and quality of the noodles.

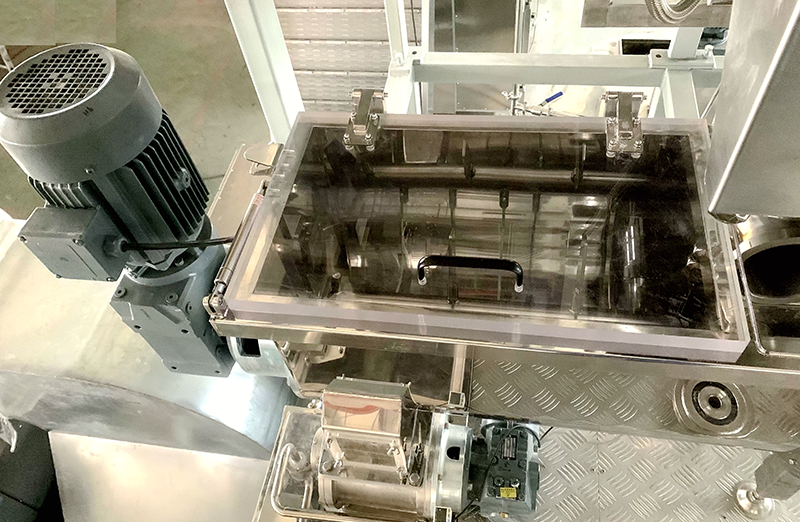

SHORT CUT PASTA PRODUCTION LINE