Email: [email protected]

2024.08.01

2024.08.01

Industry News

Industry News

Drying Method: In hakka noodle production lines, drying methods primarily focus on hot air drying and steam drying. Hot air drying involves passing heated air over the noodles to remove moisture gradually. This method is effective because it allows for precise control over temperature and airflow, ensuring uniform drying throughout the noodles. Steam drying, on the other hand, uses indirect steam heat to gently dry the noodles. It is particularly suitable for delicate noodles that require a softer drying process to preserve texture and flavor.

Drying Temperature and Time: The drying temperature and duration are critical parameters controlled during the drying process. Typically, the temperature ranges between 50°C to 80°C, depending on the thickness and composition of the noodles. Thinner noodles may require lower temperatures and shorter drying times, while thicker noodles might need higher temperatures and longer drying durations. These parameters are carefully adjusted to achieve the desired moisture content in the final product, ensuring that the noodles are dried sufficiently without becoming brittle or losing their elasticity.

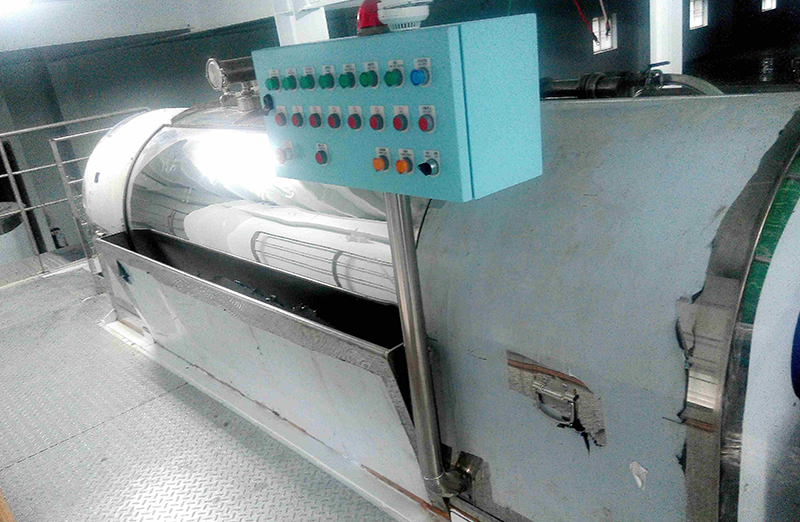

Drying Equipment: Specialized drying equipment such as continuous tunnel dryers and rotary drum dryers are integral to hakka noodle production lines. Continuous tunnel dryers feature a conveyor system that moves noodles through a controlled environment of heated air, allowing for continuous and consistent drying. Rotary drum dryers utilize rotating drums to gently tumble noodles while hot air circulates around them, ensuring even drying and preventing clumping. These machines are equipped with precise controls for temperature, humidity, and airflow, which are adjusted according to the specific requirements of the noodle recipe and production volume.

Monitoring Moisture Content: Throughout the drying process, moisture content is continuously monitored using advanced sensors and meters. These devices provide real-time data on the moisture levels of the noodles, allowing operators to make immediate adjustments to drying parameters as needed. Maintaining optimal moisture content is crucial for ensuring product quality and shelf-life. Excess moisture can lead to microbial growth and spoilage, while insufficient drying can result in hard or unevenly cooked noodles.

Quality Control: Quality control measures during drying encompass visual inspection and sensory evaluation of the noodles. Operators monitor the color, texture, and elasticity of the noodles to ensure they meet the predetermined standards for appearance and mouthfeel. Automated systems may also be employed to detect deviations in quality parameters, triggering alarms or adjustments in drying conditions.

Cooling Process: After the noodles are dried to the desired moisture content, they undergo a controlled cooling process. This phase is essential for stabilizing the noodles' temperature and texture before packaging. Cooling prevents condensation and moisture reabsorption, which could affect the noodles' integrity and shelf-life. Cooling methods include ambient air cooling or specialized cooling tunnels equipped with fans and airflow controls to expedite the process efficiently.

Packaging Readiness: Once cooled, the noodles are ready for packaging. Automated packaging systems integrated into the production line ensure hygienic handling and precise portioning of noodles into bags or containers. Packaging machinery may include weighers, sealers, and labeling systems that operate seamlessly to meet production demands. Packaging materials are selected based on their suitability for maintaining freshness and preventing moisture absorption, thereby preserving the quality of the noodles during storage and distribution.