Email: [email protected]

2024.05.27

2024.05.27

Industry News

Industry News

The drying process for short cut pasta is a critical stage in production, as it affects the final product's quality, shelf life, and texture. The management and control of this process on a short cut pasta production line typically involve several steps and technologies:

Pre-Drying Phase Optimization: Before the pasta enters the main drying chambers, the pre-drying phase plays a pivotal role in setting the stage for drying. This initial step isn't merely about moisture reduction; it's about ensuring the pasta's surface is sufficiently stabilized to withstand the rigors of the subsequent drying process. The temperature and airflow dynamics within the pre-drying chambers are meticulously calibrated to strike a delicate balance between moisture removal and surface integrity preservation.

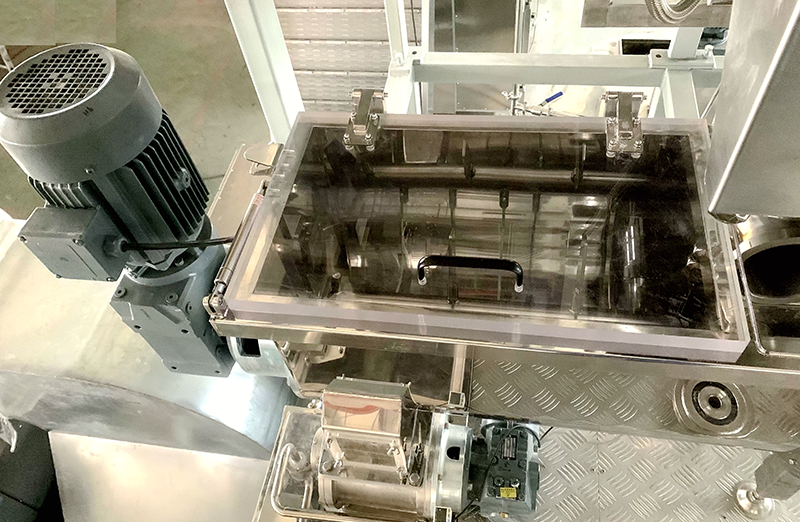

Sophisticated Drying Chamber Design: The main drying chambers or tunnels are engineering marvels designed to exert precise control over every aspect of the drying environment. These chambers feature intricate configurations of heating elements, insulation materials, and airflow ducts to create a controlled atmosphere conducive to efficient moisture evaporation. Special attention is paid to minimizing heat loss, optimizing airflow patterns, and spatial utilization to accommodate large-scale production demands.

Temperature Profiling and Control Precision: Within the drying chambers, temperature regulation is not a one-size-fits-all affair. Instead, it's a carefully orchestrated symphony of temperature zones, each tailored to the specific needs of the pasta as it progresses through the drying process. Advanced temperature profiling techniques ensure that the pasta experiences gradual but consistent temperature transitions, minimizing thermal shock and promoting uniform drying from core to surface.

Humidity Modulation Mastery: Humidity control is where the magic truly happens in the drying process. From the moment the pasta enters the drying chambers to the point of its triumphant exit, humidity levels are delicately manipulated to achieve drying kinetics. At the outset, elevated humidity levels create a protective moisture barrier around the pasta, preventing premature surface hardening and ensuring even moisture distribution. As drying progresses, humidity is gradually reduced to facilitate the efficient removal of residual moisture without compromising product texture or integrity.

Dynamic Airflow Management: The key to uniform drying lies in the artful manipulation of airflow patterns within the drying chambers. High-performance fans, strategically positioned baffles, and precision-engineered ductwork collaborate to orchestrate a symphony of air currents that envelop each pasta piece in a cocoon of gently circulating warmth. By modulating airflow velocity, direction, and distribution, the production line ensures that no corner goes unventilated, no pasta piece goes untouched, and no moisture molecule lingers where it shouldn't.

Integrated Sensor Networks and AI-driven Control Systems: Behind the scenes, a sophisticated network of sensors is hard at work, continuously monitoring the drying environment and feeding real-time data to an AI-driven control system. These sensors, ranging from temperature and humidity probes to moisture content analyzers, provide granular insights into the drying process's every nuance. Leveraging machine learning algorithms and predictive modeling techniques, the control system dynamically adjusts drying parameters on the fly, preempting potential deviations and optimizing performance for peak efficiency and product quality.

SHORT CUT PASTA PRODUCTION LINE